In the Flow measurement chapter of Fluid mechanics we deal with the applications of Bernoulli equation applicable to many situations, not just the pipe flow. Various measurement apparatus such as Venturimeter, Orifice meter, Pitot Tube, etc are dealt with in this chapter.

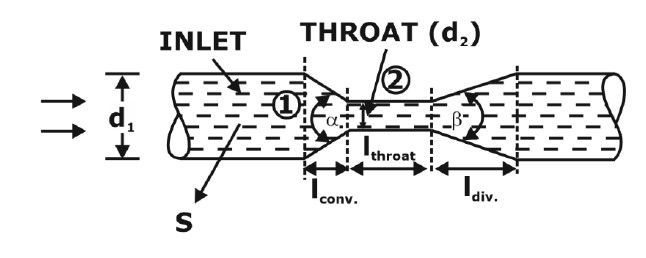

1. Venturi meter

- A device that is used to measure discharge.

- It is always used in a way that the upstream part of the flow takes place through the shorter conical portion while the downstream part of the flow takes place through the longer one as such an arrangement reduces the loss of energy due to separation in the diverging portion.

- Angle of convergence (α) = 20 — 22°

- Angle of divergence (β) = must be below 7° (To avoid Boundary layer separation)

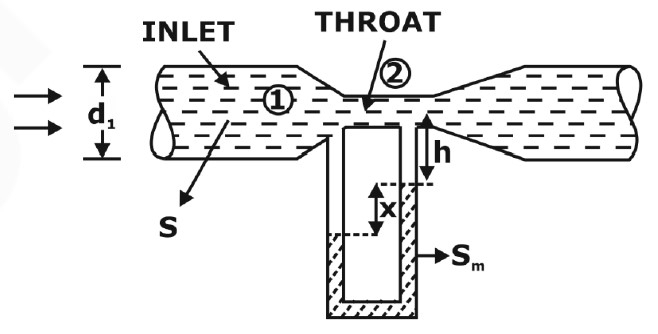

- Consider, a section (1) at inlet and section (2) is at throat diameter of venturi-meter.

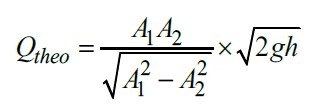

Applying Bernoulli’s equation between sections (1) & (2) and taking (z1 = z2) for horizontal pipe, We get following expression:

Applying Bernoulli’s equation between sections (1) & (2) and taking (z1 = z2) for horizontal pipe, We get following expression:

- Theortical discharge is given by:

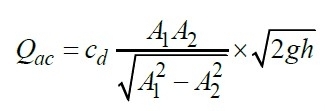

- Actual discharge is given by:

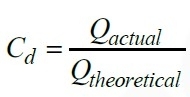

- Where cd is the coefficient of the discharge and its values is always less than one and is defined as the ratio of actual discharge to the theoretical discharge. Losses due to friction are taken into account in actual discharge. Thus, we include a coefficient of discharge (Cd=0.9)

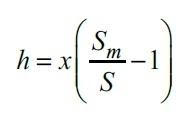

- Calculation of h:

When the manometric fluid has higher specific gravity (Sm) than the specific gravity of

When the manometric fluid has higher specific gravity (Sm) than the specific gravity of

the flowing fluid(S), then:

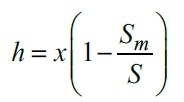

The manometric fluid has a lower specific gravity (Sm) than the specific gravity of

the flowing fluid(S), then:

Venturimeter Design Note Point:

- The diffuser ensures a gradual and steady deceleration after the throat so that the rise in pressure rises to something near that before the meter.

- The diffuser angle is usually between 6° and 8° .

- The wider flow might cause separation from the walls increasing energy loss.

- If the angle is kept low, the meter becomes very long and pressure losses again become significant.

- The efficiency of the diffuser of increasing pressure back to the original value is very rarely greater than 80%.

- Care must be taken while connecting the manometer so that no burrs are formed.

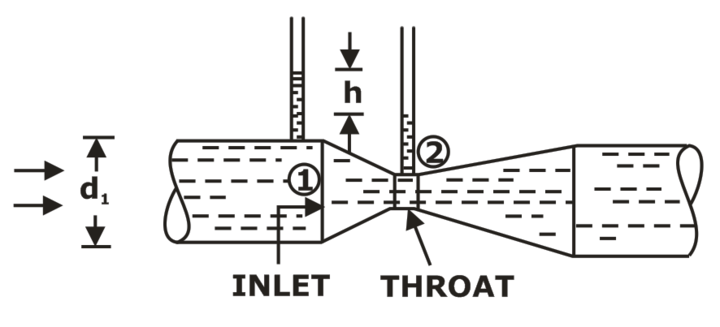

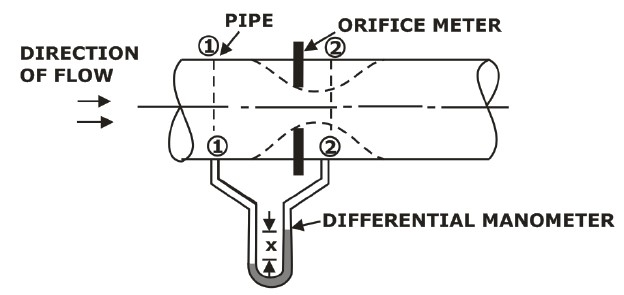

2. Orifice-meter

- A simpler and cheaper arrangement for the measurement of flow through a pipe is provided by an Orifice meter.

- It is a thin circular plate with a sharp-edged concentric circular hole in it.

- The losses are very high in the case of an orifice meter and that is why the value of Cd is low.

- The coefficient of discharge (Cd) of an orifice meter lies between 0.68 to 0.74

Applying Bernoulli’s equation between sections (1) & (2) and taking (z1 = z2) for horizontal pipe, We get the following expression:

Applying Bernoulli’s equation between sections (1) & (2) and taking (z1 = z2) for horizontal pipe, We get the following expression:

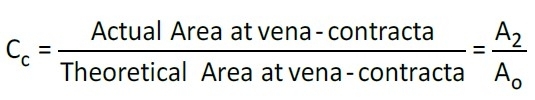

- The coefficient of contraction is given by (Cc):

Where: A0 = area of the orifice. - Discharge (Q) is given by:

- The losses in the case of orifice meter are high because the convergence of area is sudden and hence leading to losses while the losses in the case of venturi meter are less because the convergence of area is gradual and slow and hence losses are less.

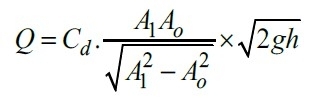

3. Pitot Tube

- The Pitot tube is a simple velocity measuring device work on the principle of stagnation point.

- At this point, velocity is zero

- Using the Bernoulli equation, the pressure at this point can be calculated.

- Two piezometers, one as usual and one as a Pitot tube within the pipe are used such as

- The above expression is for velocity from two pressure measurements and the application of the Bernoulli equation.

- Pitot Static Tube combines these tubes and they can then be easily connected to a manometer.

- Advantages of Pitot tube:

- Simple to use (and analyse)

- Gives velocities (not discharge)

- May block easily as the holes are small

- Cd Values:

For Venturi meter: 0.95 to 0.98

For Orifice meter: 0.60 to 0.65

For Flow Nozzle: 0.70 to 0.80

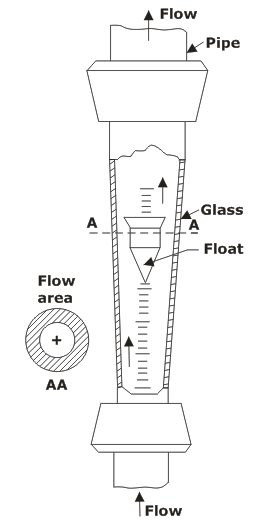

4. Rotameter

- It is a constant pressure drop variable area meter.

- Its use is limited to vertical pipelines.

- The accuracy of Rotameter is also very less (around 2%), compared to other types of flow meters. But the major advantages of rotameter are, Its simple construction, readiness to installation and the direct calibration of flow rate without the help of any other device, e.g. differential pressure sensor etc are some of its advantages.

- For the measurement of a large flow rate, the rotameter is normally placed in a bypass line.

- Variation of the density of the fluid and the presence of viscous force providing an additional force to the float are the major sources of error in this device.

No comments:

Post a Comment

Knowing brings controversy