HEAT EXCHANGERS:

Introduction

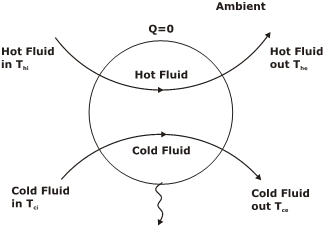

Heat exchanger is a steady flow adiabatic device (open system) in which two flowing fluids exchange or transfer heat between them without using or gaining any heat from the ambient.

Examples:

(1) Economizer [Flue gases – Feed water]

(2) Air Preheater [Hot gases – Combustion air]

(3) Superheater [Flue gases – dry saturated Steam]

(4) Cooling Tower [Hot water –Atmosphere air]

(5) Jet Condenser [Steam – cold water]

(6) Oil cooler

(7) Steam Condenser (Vapour – Liquid): Steam condenser is a shell & tube Heat Exchanger.

From thermodynamics, we know that heat transferred in a constant pressure process is equal to change in enthalpy of fluid and as we commonly assume in any heat exchanger that both hot & cold fluids are flowing through the heat exchanger at constant pressure.

Rate of decrease of enthalpy of hot fluid = Rate of increase of enthalpy of cold fluid

CLASSIFICATION OF HEAT EXCHANGERS ON BASIS OF CONTACT:

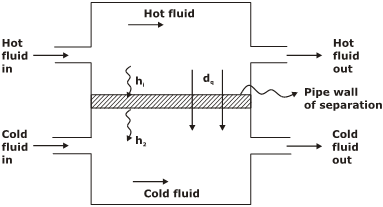

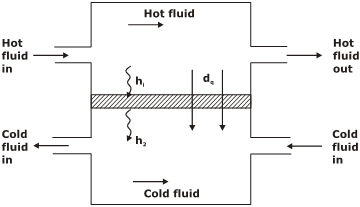

(i) INDIRECT CONTACT TRANSFER TYPE HEAT EXCHANGERS,

In this type of heat exchangers, both hot & cold fluids do not come into direct contact with each other but the transfer of heat occurs between them through a pipe wall of separation.

Examples:

(1) Surface condenser

(2) Economizer

(3) Superheater

(ii) DIRECT CONTACT TYPE HEAT EXCHANGER

In this type of heat exchanger, both hot & cold fluids physically mix up with each other & exchange heat.

Example:

(1) Cooling Tower

(2) Jet condenser

CLASSIFICATION OF HEAT EXCHANGER ON BASIS OF RELATIVE DIRECTION:

(i) PARALLEL FLOW HEAT EXCHANGER

In this heat exchanger, both Hot & Cold Fluid travel in the same direction parallel to each other.

(ii) COUNTER FLOW HEAT EXCHANGER

In this heat exchanger, Hot & Cold Fluid travel in the opposite direction parallel to each other.

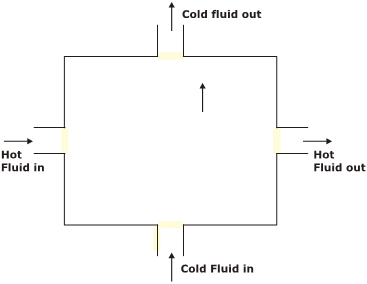

(iii) CROSS FLOW HEAT EXCHANGER

In this heat exchanger, Hot & Cold Fluid travel in perpendicular direction with respect to each other.

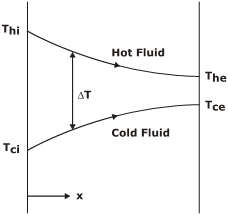

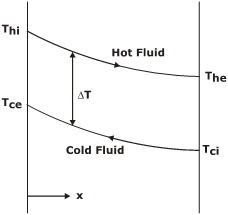

TEMPERATURE PROFILES OF HOT AND COLD FLUIDS:

(i) PARALLEL FLOW HEAT EXCHANGER

(ii) COUNTER FLOW HEAT EXCHANGER

The variation of ΔT with respect to x is much more pronounced in parallel flow heat exchanger as compared to that in counter flow heat exchanger.

LOGARITHMIC MEAN TEMPERATURE DIFFERENCE (LMTD) OF HEAT EXCHANGER

Logarithmic mean temperature difference is that constant temperature difference (maintained throughout heat exchanger) which would give same amount of heat transfer.

Q = U A ΔTm

Where,

Q = total Heat Transfer Rate between hot & cold fluid

U = Overall Heat Transfer coefficient

ΔTm = Logarithmic Mean Temperature Difference between hot and cold fluid

A = Total Heat Transfer Area of Heat Exchanger

(i) LMTD OF PARALLEL FLOW HEAT EXCHANGER

At x = 0, ΔT = ΔTi = Thi – Tci

At x = L, ΔT = ΔTe = The - Tce

(ii) LMTD of COUNTER FLOW HEAT EXCHANGER

At x = 0, ΔT = ΔTi = Thi – Tce

At x = L, ΔT = ΔTe = The – Tci

For the same inlet & exit temperature of hot & cold fluids, The value of LMTD for counter-flow heat exchanger is more than that for parallel flow heat exchanger.

LMTD FOR CROSS FLOW HEAT EXCHANGER:

LMTD for cross-flow heat exchanger can be obtained as

Where, F = correction factor,

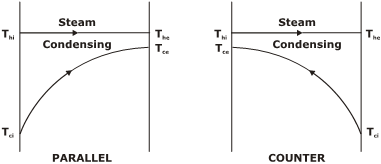

SPECIAL CASE REGARDING LMTD

When one of the fluids is undergoing change of phase like in steam condenser or evaporator or steam generator then,

Steam condenser:

(ΔTm)parallel flow = (ΔTm)counter flow

EFFECTIVENESS OF HEAT EXCHANGER

It is defined as the ratio between actual heat transfer rate that is taking place between hot & cold fluids to the maximum possible heat transfer rate that can occur between them,

qactual = Rate of enthalpy change of either fluid

qactual = mh Cph (Thi – The) = mc Cpc (Tce – Tci)

qmax = maximum possible heat transfer rate= (m Cp)small × (Thi – Tci)

Where (m Cp)small is the smaller capacity rate between hot & cold fluids.

Number of Transfer Units (NTU)

It is defined as the ratio between product of UA & small capacity rate between hot & cold fluids.

NTU being directly proportional to the area of the heat exchanger indicates overall size of the heat exchanger.

Capacity Rate Ratio (C):

C will become zero when one of the fluids is undergoing change of phase like steam condenser.

For any Heat Exchanger, ϵ = f (NTU, C)

Effectiveness for the parallel flow heat exchanger:

Effectiveness for the counterflow heat exchanger:

SPECIAL CASES

CASE 1: when one of the fluids is undergoing change of phase, then C is equal to zero.

Hence,

CASE 2: The other extreme value of C=1, when both hot & cold fluids have equal capacity rates (mh Cph = mc Cpc)

No comments:

Post a Comment

Knowing brings controversy