Exomechanicals

Based on hoshiarpur, Punjab,India, exomechanicals is basically brainchild of Wilson Aziz , & his vision to guide young engineers becouse he realised that the current curriculum syllabus is not up to the mark as per industrial standards he dedicated his life to improve the level of education in engineering domain

Winzo

Wednesday, May 10, 2023

What is smartfactory

Tuesday, January 10, 2023

Plc panel components and design

what is plc

what is PLC  Plc or plc controller is basically an board used to programming the machine in a preordely way, likewise i showing in above figures this one is designed for an rac plant,

Plc or plc controller is basically an board used to programming the machine in a preordely way, likewise i showing in above figures this one is designed for an rac plant,

In this article I will discuss with you the , wiring connection and components of plc, in terms of RAC PLANT

Let's learn about this with an example u need to charge your smartphone so u need to use an charger to charge your phone for continuous supply of voltage

Same in the sense SMPS have same purpose it distribute constant voltage 12/24 voltage around the panel in case your are using module box

MCB- MCB are available in the difference variant in the market , if it's. 100 amp. Plus then it's called as MCCB

THIS IS SERVED IN THE CIRCUIT IF THERES HIGH VOLTAGE OR AMPRE DIFFERENCE JN THE CIRCUIT, IN THAT CASE MCB going to trip it can be single pole or 3 poles

in 4 connection MCB the fourth one is for neutral wire connection.

CONTACTORS - Contractors are basically coins those serves inthe circuit to of & offf the motors , when you turned on/ off the switch,

These are directly connected to the T1.T2.T3 point of the MCB, with each face RYB, RESPECTIVELY

THE A1 &A2 points are for coils to turn on / off,

The start stop switch is added between these two

.

The MCB is really expensive & the compressor & motors repair cost is also high if overload doesn't worked properly the contactor simply burn to safeguard the compressor /motor

Overload , overload is also served for the safety fo contactor as it doesn't have any safety of its own,

The MCB is really expensive & the compressor & motors repair cost is also high if overload doesn't worked properly the contactor simply burn to safeguard the compressor /motor

Saturday, March 27, 2021

shape factor or view factor

SHAPE FACTOR OR VIEW FACTOR OR CONFIGURATION FACTOR:

Radiation heat transfer between surfaces depends upon the orientation of the surfaces relative to each other as well as their radiation properties and temperatures.

To account for the effects of orientation on radiation heat transfer between the surfaces,

a new parameter VIEW FACTOR is defined which is purely geometric quantity and is independent of radiation properties and temperatures.

Assumptions:

- The surfaces are diffuse emitter.

- The radiation that strikes a surface need not to be absorbed by that surface.

- Radiation that strikes a surface after being reflected by other is not considered in the evaluation of view factor.

The radiation shape factor is represented by the symbol Fij ,

which means the shape factor form a surface, Ai to another surface Aj.

Thus the radiation shape factor F12 of surface A1 to surface A2 is

SHAPE FACTOR RELATIONS:

(i) RECIPROCITY RELATION:

A1F12 = A2F21

Reciprocity Relation is valid between any two surfaces even when there are more than two number of surfaces involved in Radiation Heat Exchange.

(ii) SUMMATION RULE:

If there are n number of surfaces involved in any radiation heat exchange then.

F11 + F12 + F13 + …………….F1n = 1

F21 + F22 + F23 + ……………. F2n = 1

.

Fn1 + Fn2 + Fn3 + ………..Fnn + 1

TOTAL SURFACES FOR VIEW FACTORS FOR N SURFACES OF AN ENCLOSURE

- Numbers of relation given by summation rule =N

- Numbers of relations given by reciprocity rule,

- The total numbers of view factors that need to be evaluated directly,

SUPERPOSITION RULE:

F1-(2,3) = F1-2 + F1-3

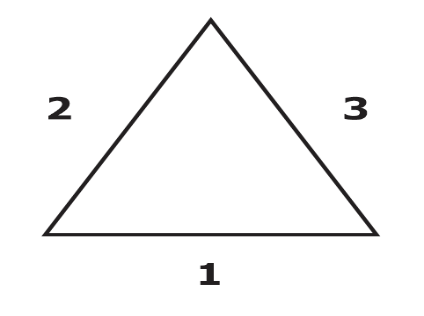

SYMMETRY RULE:

Two or more surfaces that posses symmetry about a third surface will have identical view factors from that surface.

If the surface 2 and 3 are symmetric about surface 1 then F1-2=F1-3

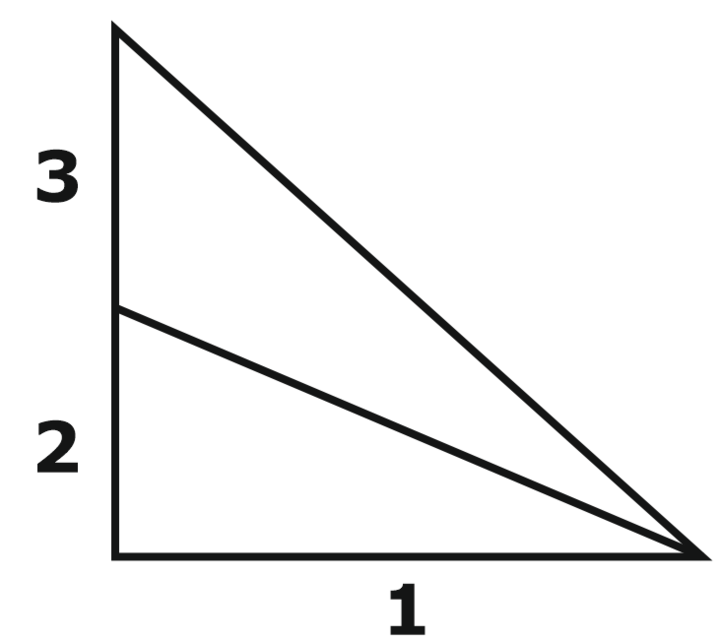

GENERAL CASES:

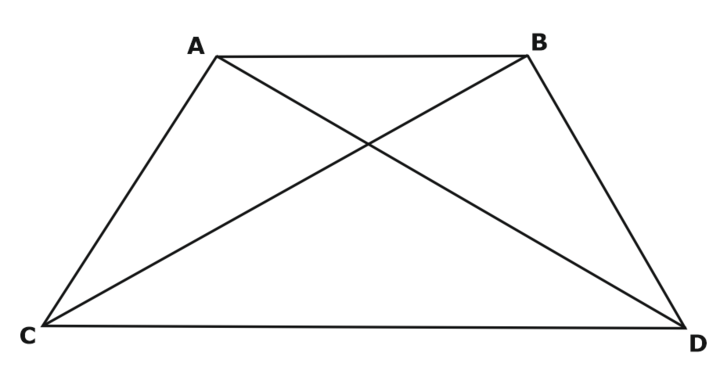

CROSS STRING METHOD:

The each length is assumed to Be a strings connected between two points.

Cross Strings → The strings which crosses each other.

Uncrossed strings → The strings which do not cross each other.

Li = length of string on surface i.

AB → 1 surface

CD → 2 surface

Special Case:

(Length)1 = (Length)2 Both surface are infinite in plane perpendicular to plane of paper.

radiation network analysis

RADIATION NETWORKS:

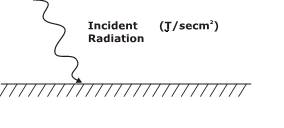

IRRADIATION (G)

Irradiation (G) is defined as the total thermal radiation incident upon a surface per unit time per unit area (in W/m2)

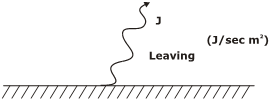

RADIOSITY (J):

The total thermal radiation leaving a surface per unit time & per unit area is called radiosity of the surface.

J = Emitted Energy + Reflected Part of Incident energy,

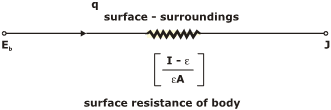

The net radiation heat exchange between the surface & all of its surroundings is given by,

The equivalent radiation circuit is,

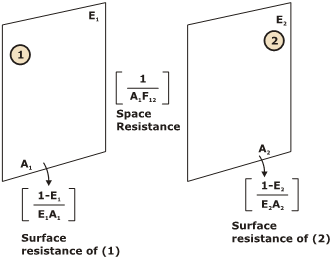

Radiation heat exchange between two finite surfaces:

,The equivalent radiation circuit is

This space resistance shall exist in the space between two surfaces exchanging heat by radiation.

Complete radiation network between two surfaces exchanging heat by radiation:

Therefore,

APPLICATIONS OF RADIATIONS NETWORKS:

(i) Radiation Exchange Between two Infinitely Large Plane Surfaces:

(ii) TWO INFINITELY LONG CYLINDERS:

Therefore,

RADIATION SHIELDS:

F12 = 1, F21 = 1

Since surfaces are very large

A1 = A2 = A3 = 1 and F13 = 1, F32 = 1

Therefore,

radiation heat transfer

RADIATION HEAT TRANSFER:

(i) Thermal energy emitted by matter as a result of vibrational and rotational movements of molecules, atoms and electrons.

(ii) The energy is transported by electromagnetic waves (or photons).

(iii) Radiation requires no medium for its propagation, therefore, can take place also in vacuum.

BASIC DEFINITIONS:

TOTAL HEMISPHERICAL EMISSIVE POWER (E)

(i) It is defined as the radiation energy emitted from the surface of a body per unit time & per unit area in all possible hemispherical directions integrated over all the wavelengths (in J/s m2 or W/m2).

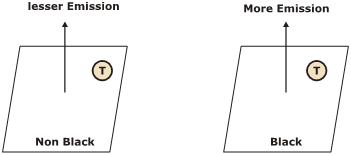

BLACK BODY

(i) Different bodies emits different amount of radiation even if they are at same temperature.

(ii) A body which emits maximum amount of radiation at a given temperature is known as BLACK BODY.

(iii) A black body is defined as perfect emitter and absorber of radiation.

TOTAL EMISSIVITY (Є)

Total emissivity of a body is defined as the ratio between total hemispherical emissive power of a non-black body & total hemispherical emissive power of a black body both being at the same temperature.

MONOCHROMATIC (OR) SPECTRAL EMISSIVE POWER (Eλ):

Eλ at a particular wavelength λ is defined as a quantity which when multiplied by dλ shall give the radiation energy emitted from the surface of a body per unit time per unit area in the wavelength region λ to λ + dλ.

ABSORPTIVITY (α), REFLECTIVITY (ρ) & TRANSMISSIVITY (τ)

- Absorptivity(α) is the fraction of incident radiation absorbed.

- Reflectivity(ρ) is the fraction of incident radiation reflected.

- Transmissivity (τ) is the fraction of incident radiation transmitted.

ABSORPTIVITY (α) = 50/100 = 0.5 = Fraction of radiation energy incident upon a surface which is absorbed by it.

REFLECTIVITY (ρ) = 25/100 = 0.25 = Fraction of radiation energy incident upon a surface which is reflected by it.

TRNASMISSIVITY (τ) = 25/100 = 0.25 = Fraction of radiation energy incident upon a surface which is transmitted by it.

- FOR ANY BODY

α + ρ + τ = 1

- For opaque body, which do not transmit any energy,

τ = 0, α + ρ = 1

- For black body, α = 1 [as it absorbs all energy incident]

- For white body, which reflects all energy incident ,τ = 1

LAWS OF THERMAL RADIATION:

KIRCHOFF’S LAW OF RADIATION:

The law states that whenever a body is in thermal equilibrium with its surrounding’s its emissivity is equal to its absorptivity.

α = ϵ

STEFAN BOLTZMANN’S Law:

The law states that the total hemispherical emissive power of a black body is directly proportional to fourth power of the absolute temperature of black body.

Stefan BoltzmannConstant= 5.67 × 10-8 W/m2 k4

PLANCK’S LAW OF THERMAL RADIATION:

The planck law describes the theoretical spectral distribution for the emissive power of a black body which is the amount of radiation energy emitted by a blackbody at a thermodynamic temperature T per unit time per unit surface area and per unit wavelength.

WEIN’S DISPLACEMENT LAW:

The wavelength at which Ebλ will be maximum at a specified temperature can be found out by differentiating Ebλ w.r.t λ and then putting equal to zero.

We get, λmT = 2897.8 μmK

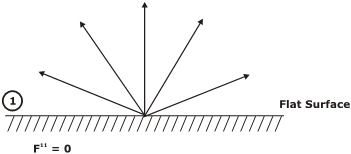

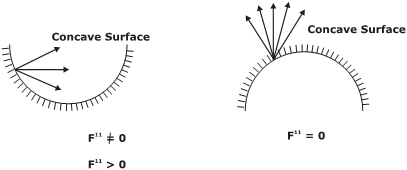

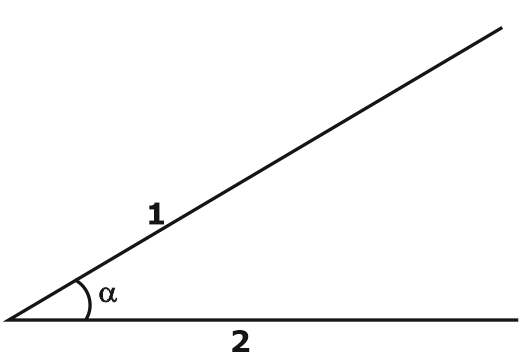

LAMBERT’S COSINE LAW

The intensity of radiation in a direction θ from the normal to a diffuse emitter is proportional to cosine of the angle θ.

I= In cos θ, In = normal intensity of radiation

RADIATION INTENSITY:

The ideal intensity Ib is defined as the energy emitted from an ideal body(black body which is diffuse emitter) ,per unit projected area, per unit time ,per unit solid angle.

heat exchangers

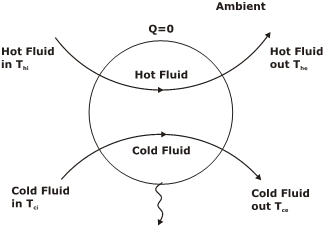

HEAT EXCHANGERS:

Introduction

Heat exchanger is a steady flow adiabatic device (open system) in which two flowing fluids exchange or transfer heat between them without using or gaining any heat from the ambient.

Examples:

(1) Economizer [Flue gases – Feed water]

(2) Air Preheater [Hot gases – Combustion air]

(3) Superheater [Flue gases – dry saturated Steam]

(4) Cooling Tower [Hot water –Atmosphere air]

(5) Jet Condenser [Steam – cold water]

(6) Oil cooler

(7) Steam Condenser (Vapour – Liquid): Steam condenser is a shell & tube Heat Exchanger.

From thermodynamics, we know that heat transferred in a constant pressure process is equal to change in enthalpy of fluid and as we commonly assume in any heat exchanger that both hot & cold fluids are flowing through the heat exchanger at constant pressure.

Rate of decrease of enthalpy of hot fluid = Rate of increase of enthalpy of cold fluid

CLASSIFICATION OF HEAT EXCHANGERS ON BASIS OF CONTACT:

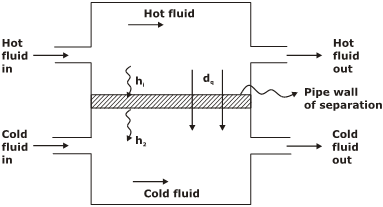

(i) INDIRECT CONTACT TRANSFER TYPE HEAT EXCHANGERS,

In this type of heat exchangers, both hot & cold fluids do not come into direct contact with each other but the transfer of heat occurs between them through a pipe wall of separation.

Examples:

(1) Surface condenser

(2) Economizer

(3) Superheater

(ii) DIRECT CONTACT TYPE HEAT EXCHANGER

In this type of heat exchanger, both hot & cold fluids physically mix up with each other & exchange heat.

Example:

(1) Cooling Tower

(2) Jet condenser

CLASSIFICATION OF HEAT EXCHANGER ON BASIS OF RELATIVE DIRECTION:

(i) PARALLEL FLOW HEAT EXCHANGER

In this heat exchanger, both Hot & Cold Fluid travel in the same direction parallel to each other.

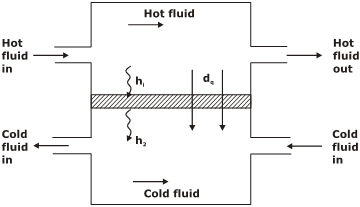

(ii) COUNTER FLOW HEAT EXCHANGER

In this heat exchanger, Hot & Cold Fluid travel in the opposite direction parallel to each other.

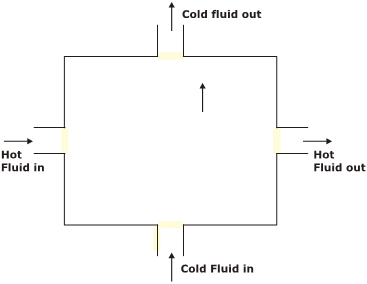

(iii) CROSS FLOW HEAT EXCHANGER

In this heat exchanger, Hot & Cold Fluid travel in perpendicular direction with respect to each other.

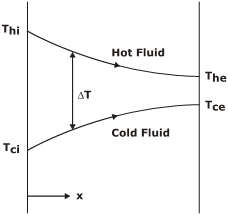

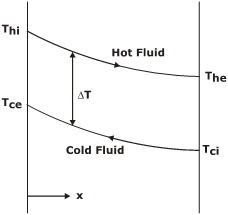

TEMPERATURE PROFILES OF HOT AND COLD FLUIDS:

(i) PARALLEL FLOW HEAT EXCHANGER

(ii) COUNTER FLOW HEAT EXCHANGER

The variation of ΔT with respect to x is much more pronounced in parallel flow heat exchanger as compared to that in counter flow heat exchanger.

LOGARITHMIC MEAN TEMPERATURE DIFFERENCE (LMTD) OF HEAT EXCHANGER

Logarithmic mean temperature difference is that constant temperature difference (maintained throughout heat exchanger) which would give same amount of heat transfer.

Q = U A ΔTm

Where,

Q = total Heat Transfer Rate between hot & cold fluid

U = Overall Heat Transfer coefficient

ΔTm = Logarithmic Mean Temperature Difference between hot and cold fluid

A = Total Heat Transfer Area of Heat Exchanger

(i) LMTD OF PARALLEL FLOW HEAT EXCHANGER

At x = 0, ΔT = ΔTi = Thi – Tci

At x = L, ΔT = ΔTe = The - Tce

(ii) LMTD of COUNTER FLOW HEAT EXCHANGER

At x = 0, ΔT = ΔTi = Thi – Tce

At x = L, ΔT = ΔTe = The – Tci

For the same inlet & exit temperature of hot & cold fluids, The value of LMTD for counter-flow heat exchanger is more than that for parallel flow heat exchanger.

LMTD FOR CROSS FLOW HEAT EXCHANGER:

LMTD for cross-flow heat exchanger can be obtained as

Where, F = correction factor,

SPECIAL CASE REGARDING LMTD

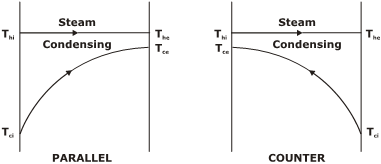

When one of the fluids is undergoing change of phase like in steam condenser or evaporator or steam generator then,

Steam condenser:

(ΔTm)parallel flow = (ΔTm)counter flow

EFFECTIVENESS OF HEAT EXCHANGER

It is defined as the ratio between actual heat transfer rate that is taking place between hot & cold fluids to the maximum possible heat transfer rate that can occur between them,

qactual = Rate of enthalpy change of either fluid

qactual = mh Cph (Thi – The) = mc Cpc (Tce – Tci)

qmax = maximum possible heat transfer rate= (m Cp)small × (Thi – Tci)

Where (m Cp)small is the smaller capacity rate between hot & cold fluids.

Number of Transfer Units (NTU)

It is defined as the ratio between product of UA & small capacity rate between hot & cold fluids.

NTU being directly proportional to the area of the heat exchanger indicates overall size of the heat exchanger.

Capacity Rate Ratio (C):

C will become zero when one of the fluids is undergoing change of phase like steam condenser.

For any Heat Exchanger, ϵ = f (NTU, C)

Effectiveness for the parallel flow heat exchanger:

Effectiveness for the counterflow heat exchanger:

SPECIAL CASES

CASE 1: when one of the fluids is undergoing change of phase, then C is equal to zero.

Hence,

CASE 2: The other extreme value of C=1, when both hot & cold fluids have equal capacity rates (mh Cph = mc Cpc)

What is smartfactory

Smart factories have emerged as the future of manufacturing, revolutionizing industrial processes through advanced technologies and automati...

-

Fluid Kinematics - Kinematics is the branch of classical mechanics that describes the motion of bodies and systems without consideration of...

-

A shaft is said to be under pure torsion when it is subjected to two equal & opposite couples in a plane perpendicular to the longitudin...

-

Control-Volume Analysis of Mass, Momentum and Energy is an important topic of Fluid mechanics that deals with topics such as control mass, c...