Stress and Strain is the first topic in Strength of Materials which consist of various types of stresses, strains and different properties of materials which are important while working on them.

Stress: The force of resistance per unit area, offered by a body against deformation is known as stress.

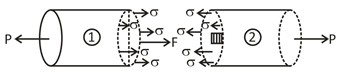

Fig.1: Stress

It is denoted by a symbol ‘σ’. And mathematically expressed as

As particular stress generally holds true only at a point, therefore it is defined mathematically as

TYPES OF STRESSES:

only two basic stresses exist.

(1) Normal stress and

(2) Shear stress.

(i) Normal stresses:

If the force applied are perpendicular or normal to areas concerned, then these are termed as normal stresses.

The normal stresses are generally denoted by a Greek letter (σ).

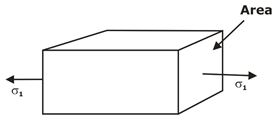

Fig.2 Uniaxial Normal Stress

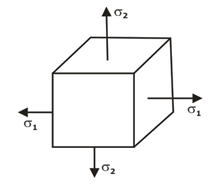

Fig.3: Biaxial Normal Stress

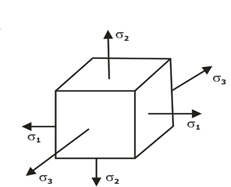

Fig.4: Triaxial Normal Stress

Tensile or compressive stresses:

The normal stresses can be either tensile or compressive depending upon the direction of the load.

Sign convention: The tensile forces are termed as (+ve ) while the compressive forces are termed as negative (-ve).

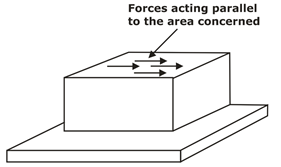

(ii)Shear Stress:

when cross-sectional area of a block of material is subject to a distribution of forces which are parallel to the area concerned. Such forces are associated with a shearing of the material, are known as shear forces. The stress produced by these forces are known as shear stresses.

Fig.5: Shear stress

It is generally denoted by ‘τ’ and expressed as

The complementary shear stresses are equal in magnitude.

The same form of relationship can be obtained for the other two pair of shear stress components to arrive at the relations,

τxy=τyx

τyz=τzy

Sign convections for shear stresses:

Shear stress tending to turn the element Clockwise is taken as Positive.

Shear stress tending to turn the element Anticlockwise is taken as Negative.

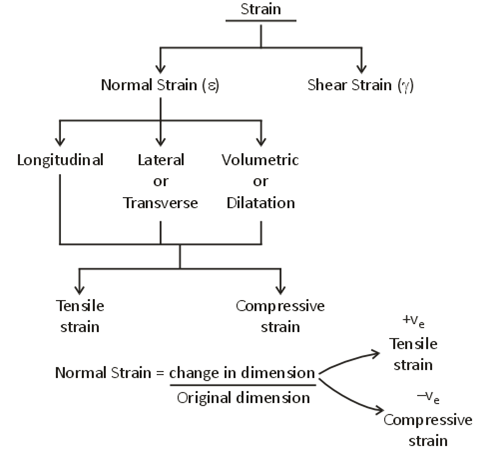

STRAIN

When a prismatic bar is subjected to axial load, it undergoes a change in length, as indicated in Figure. This change in length is usually called deformation.

Fig.6: Deformation of bar under axial load

If the axial force is tensile, the length of the bar is increased, while if the axial force is compressive, there is shortening of the length of the bar.

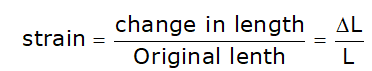

The deformation (i.e. elongation or shortening) per unit length of the bar is termed as strain and denoted by ε or e.

Fig.7: Classification of strain

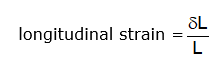

(i) Longitudinal strain:

The ratio of axial deformation along the length of the applied load to the original length of the body is known as longitudinal (or linear) strain.

L = Length of the body,

P = Tensile force acting on the body,

δL = Increase in the length of the body in the direction of P.

Then,

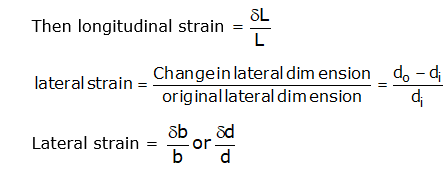

(ii) Lateral strain:

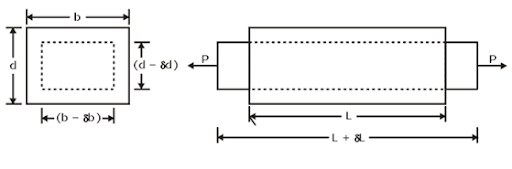

The strain at right angles to the direction of applied load is known as lateral strain. Let a rectangular bar of length L, breadth b and depth d is subjected to an axial tensile load P. The length of the bar with increase while the breadth and depth will decrease.

δL = Increase in length,

δb = Decrease in breadth, and

δd = Decrease in depth.

Fig.8: strain

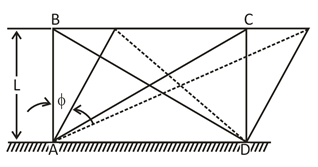

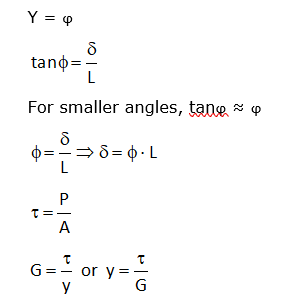

(iii)Shear Strain

Change in initial right angle between two-line elements which are parallel to x and y-axis respectively.

Fig.9: Shear strain

STRESS - STRAIN DIAGRAM

The mechanical properties of a material are determined in the laboratory by performing tests on small specimens of the material, in the materials testing laboratory. The most common materials test is the tension test performed on a cylindrical specimen of the material.

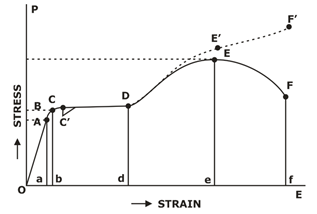

Fig.16: Stress strain Diagram

A = Proportional Limit Oa = Linear Deformation

B = Elastic Limit Ob = Elastic Deformation

C = Yield Point bd = Perfect Plastic Yielding

C’ = Lower Yield Point de = Strain hardening

E = Ultimate Strength ef = Necking

F = Rupture Strength/ Fracture strength

It is customary to base all the stress calculations on the original cross-sectional area of the specimen, and since the latter is not constant, the stresses so calculated are known as Nominal stresses.

LINEAR ELASTICITY: HOOKE’S LAW

The slope of stress-strain curve is called the young’s modulus of elasticity (E):

Slope of stress-strain curve,

This equation is known as Hooke’s law.

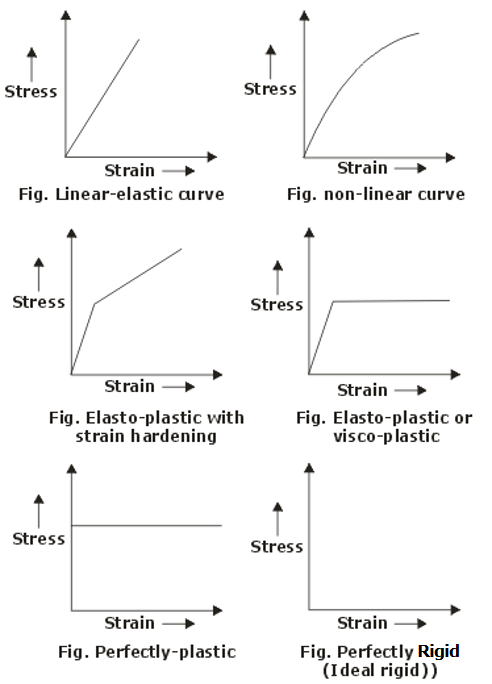

Type of Metal Behaviour

Fig.17: Stress strain Diagram

ELONGATION OF BAR UNDER DIFFERENT CONDITION

UNIFORMLY TAPERING CIRCULAR BAR

Let us now consider a uniformly tapering circular bar, subjected to an axial force P, as shown in Figure. The bar of length L has a diameter d1 at one end and d2 at the other end (d2 > d1).

Fig.18: Uniformly tapering circular bar

PRINCIPLE OF SUPERPOSITION

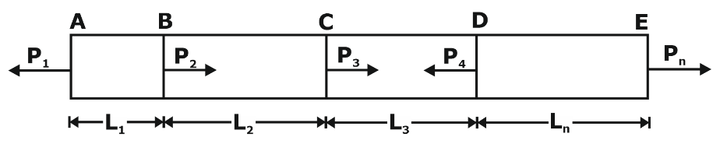

Bars In Series

Fig.19: A prismatic bar subjected to multiple loads

It stated that

"the resultant strain in bar will be equal to the algebraic sum of the strains caused by the individual forces acting along the length of the member.

Thus, if a member of uniform section is subjected to a number of forces, the resulting deformation (ΔL) is given by

No comments:

Post a Comment

Knowing brings controversy